CNC Milling of a Front Engine Accessory Drive (FEAD) Mounting Bracket

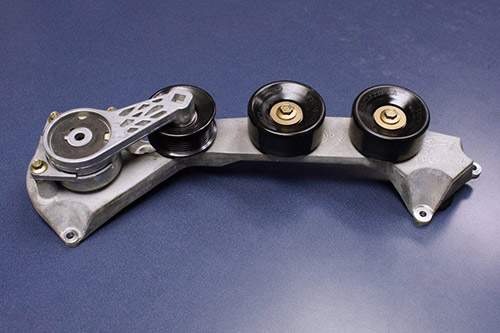

The product highlighted here is manufactured for use as a Front Engine Accessory Drive (FEAD) Mounting Bracket. The project specifications called for a high volume product with strength and precision machining.

Producing manufactured assemblies requires the versatility to allow for varied processes to be performed in-house, saving the customer time and production costs. The assembly shown here is a perfect example of precision machining and quality assembly of components.

The customer supplied engineering drawings called for dimensions of 21.5″ in length, 7″ in width, and 2.25″ in height, with tolerances of ±0.005″. Composed of A356 T6 aluminum, machining was performed on our precision CNC horizontal machining centers. Processes used include milling, drilling, and hollow milling, as well as tapping.

Functional gauge checks were used to verify dimensional integrity, before the parts were fully assembled. We manufactured 7,000 of these components for this customer, delivered in JIT shipments. To learn more about this project, see the table below or contact us directly.

Highlights of this Precision CNC Milling Project

- Product Description

-

This is an accessory drive mounting assembly.

- Precision CNC Machining Capabilities Applied/Processes

-

Primary:

CNC Milling

Drilling

Hollow MillingSecondary:

Taping

Assembly

- Equipment Used to Manufacture Part

-

Horizontal machining center

- Overall Part Dimensions

-

Length: 21.5″

Width: 7″

Height: 2.25″

- Tightest Tolerances

-

± 0.005″

- Material Used

-

A356 T6 Aluminum

- Material Finish

-

Machined

- In process testing/inspection performed

-

Functional Gage Checks

- Industry for Use

-

Automotive Industry

- Volume

-

7,000 pieces

- Delivery/Turnaround Time

-

JIT

- Delivery Location

-

Michigan

- Standards Met

-

Customer Specifications, 2D CAD Drawing

- Product Name

-

Front Engine Accessory Drive (FEAD) Mounting Bracket