Product Development Services for Iron and Aluminum Products

As a high quality precision manufacturer, we are proud to offer our customers comprehensive product development services for automotive, off road, and agricultural industries. We provide prototype design and development, specializing in creating product concepts from client ideas.

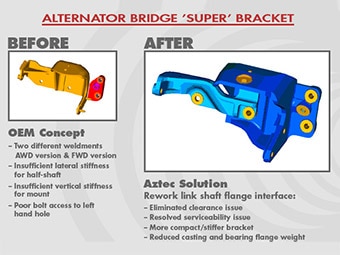

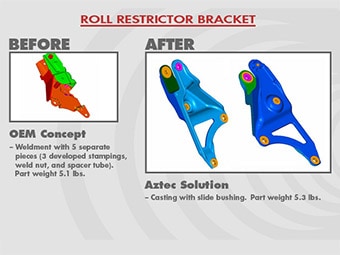

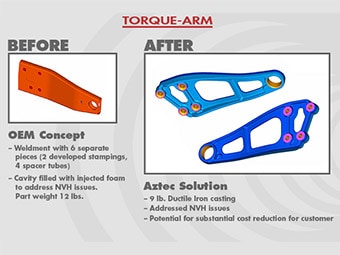

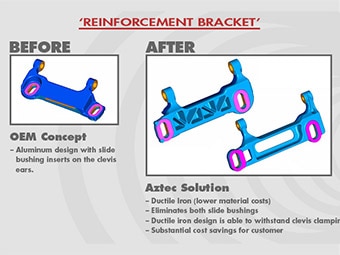

Our development process can take an idea from concept to finished products, starting with analysis by our cross functional engineering teams. We provide FEA analysis utilizing appropriate testing with black box and gray box methods, as well as CAD and Solid modeling to develop a working prototype. Existing products can be redesigned to reduce weight and cost, and perform better.

Our experience and expertise provide a solid production strategy, reducing your time to market. We work with all industry standard programs including Catia, AutoCAD, Unigraphic and Solidworks. Other services include project management, reverse engineering, design review, and developing mating parts. All of our products and processes are quality assured and meet stringent industry standards. For more about our product development services or our other capabilities, please see the table below or contact us directly.

Portfolios

Product Development Capabilities

- General Capabilities

-

Product Concept

Prototype Design & Development

Cross-Functional Engineering Teams

Black Box / Gray Box Capability

FEA Analysis

Cost Reduction

Mating Parts

Develop Design Concepts from Customer Ideas

- Process Type

-

CAD Modeling

Solid Modeling

Blueprint Detailing

- Process Development

-

Reduce Weight

Better Performance

Cost Less to Produce

- Additional Services Provided

-

Reverse Engineering

Documentation

Design Review

Project Management

- Quality

-

Statistical Process Control (SPC)

Coordinate Measuring Machine (CMM)

Additional Information

- Industry Focus

-

Automotive

Off Road

Agriculture

- Intended Applications

-

Chassis Components

Powertrain Components

- Industry Standards

-

ISO 14001

IATF16949

Q1 (Ford Motor Company)

- Lean Manufacturing

-

Cost Reduction

Quality

Delivery

Overall Customer Satisfaction

- File Formats

-

AutoCAD

Autodesk Inventor

Ungraphics / NX

Catia

SolidWorks

Creo/Pro Engineer

STEP

IGES

Fusion 360